Technical Name: BOILER OPERATOR TRAINING IN ENGLISH

Reference: 55764

Boiler Operator Training English

The Boiler Operator Training English aims to provide a solid theoretical foundation for boiler operators by developing a clear understanding of pressure, heat transfer, thermodynamics, fluid mechanics, and applied chemistry. Therefore, participants learn how physical and thermal principles govern boiler behavior, enabling them to interpret operating conditions, recognize critical variables, and understand the scientific basis behind safe and efficient boiler operation.

Moreover, the course aligns its content with the requirements of NR 13, which establishes the minimum technical and safety criteria for boiler operation. As a result, operators gain conceptual competence to support compliant decision-making, improve operational awareness, and reduce risks associated with pressurized thermal systems, even when the training scope is strictly theoretical.

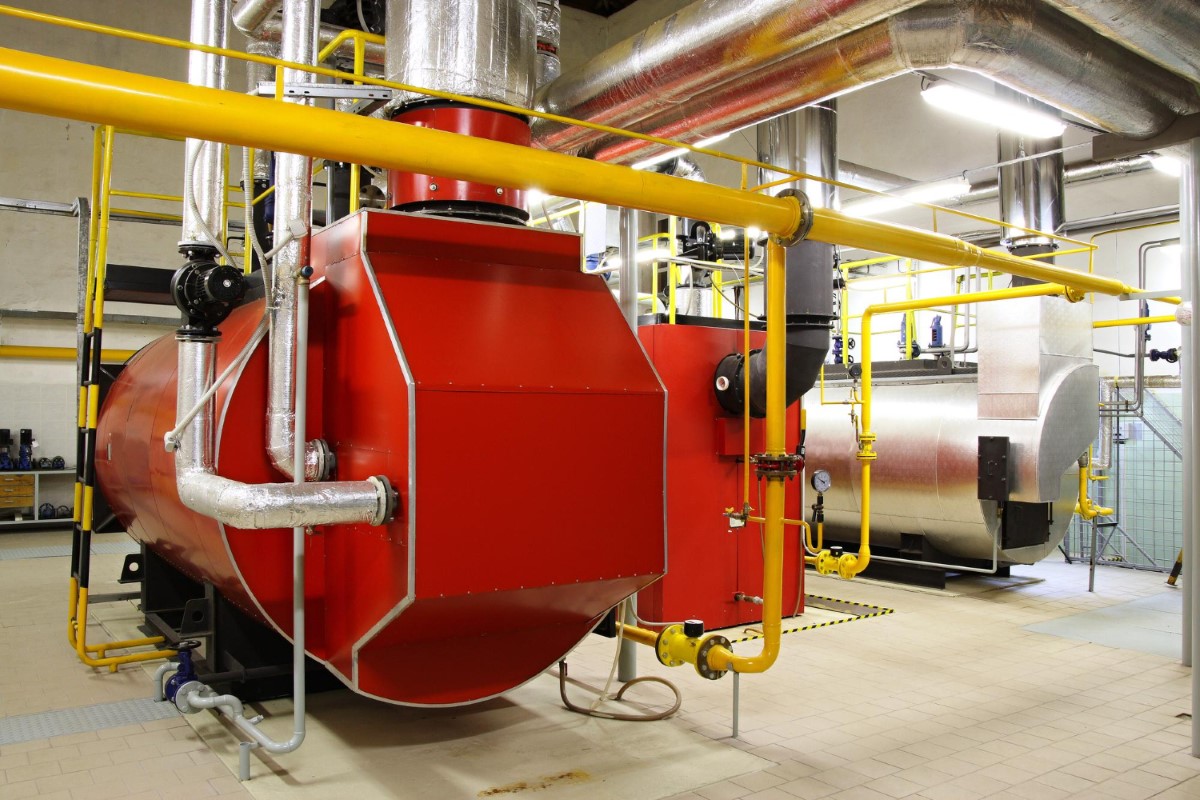

Modern boiler installation highlighting heat transfer efficiency, fluid flow control, and energy balance essential for safe and reliable boiler operation.

Who should take this boiler operator theoretical course?

This course is designed for professionals who work directly or indirectly with boiler systems and need a solid theoretical understanding of their operation. Therefore, it is suitable for boiler operators, supervisors, technicians, engineers, and safety professionals who must interpret operating conditions and technical parameters.

Furthermore, the course benefits anyone responsible for decision-making related to pressurized thermal systems. By mastering the theoretical foundations, participants strengthen their technical judgment, improve communication with inspection and maintenance teams, and support compliance with NR 13 requirements.

When is theoretical knowledge essential for boiler operation?

Theoretical knowledge is essential throughout the entire boiler lifecycle because it allows operators to understand how pressure, temperature, and fluid behavior respond to operational changes. Consequently, theory supports safer decisions and consistent actions in all operating phases.

| Operational Situation | Importance of Theoretical Knowledge |

|---|---|

| Start-up and shutdown | Understanding pressure and temperature variation |

| Normal operation | Interpreting heat transfer and fluid flow |

| Abnormal conditions | Identifying deviations and potential risks |

| Decision-making | Supporting actions aligned with NR 13 |

Boiler Operator Training English: Boiler operation depends on pressure and heat transfer principles

Boiler operation is governed by physical laws related to pressure and heat transfer, which define how energy is generated and controlled within the system.

Key aspects addressed

Pressure behavior in pressurized systems

Heat transfer mechanisms and efficiency

Relationship between temperature variation and steam generation.

Steam boiler in operation demonstrating phase change, heat transfer mechanisms, and the critical relationship between pressure, temperature, and system integrity.

Why is thermodynamics critical for boiler operators?

Thermodynamics explains how energy is introduced, transformed, and released within a boiler system. Therefore, understanding thermodynamic principles allows operators to recognize efficiency limits and the relationship between pressure, temperature, and phase change.

In addition, thermodynamics supports safer operation by clarifying how variations in operating conditions affect system stability. As a result, operators improve technical judgment and act in accordance with the safety limits established by NR 13.

Where do fluid mechanics principles apply in boiler systems?

Fluid mechanics applies across the entire boiler system because it governs how water and steam move under pressure differences and flow conditions. As a result, understanding these principles helps operators interpret system behavior and identify abnormal flow conditions.

| System Area | Fluid Mechanics Application |

|---|---|

| Feedwater lines | Flow rate and pressure control |

| Steam lines | Turbulence and pressure loss |

| Pumps | Energy conversion and fluid movement |

| Piping | Head loss and flow resistance |

Boiler Operator Training English: Chemical balance directly influences boiler safety and durability

Chemical conditions inside boiler systems directly affect corrosion, scaling, and equipment integrity.

Core concepts covered

pH control and corrosion behavior

Solubility variation with temperature

Diffusion of gases and vapors in boiler water

How does this theoretical course support compliance with NR 13?

This course supports compliance with NR 13 by providing operators with the theoretical foundation required to understand operational limits and safety principles. Consequently, participants gain clarity on how physical laws govern boiler behavior under normal and abnormal conditions.

Furthermore, by strengthening conceptual knowledge, the course reduces reliance on empirical practices and reinforces disciplined decision-making. As a result, organizations improve safety culture, technical consistency, and regulatory adherence, even when practical training is conducted separately.

Industrial boiler system operating under controlled pressure and temperature conditions, illustrating the importance of thermodynamic principles and pressure management in compliance with NR 13 requirements.

What is the important of the Boiler Operator Training English?

The Boiler Operator Training English is essential because it provides boiler operators with a solid theoretical foundation to understand how pressure, heat transfer, thermodynamics, fluid mechanics, and applied chemistry govern boiler behavior. As a result, participants develop technical awareness to interpret operating conditions correctly, recognize deviations, and make informed decisions based on physical principles rather than assumptions, which directly contributes to safer and more efficient boiler operation.

Moreover, the course reinforces compliance with NR 13, which establishes the minimum safety and technical requirements for boiler operation. By aligning theoretical knowledge with this regulation, the training strengthens risk control, supports regulatory adherence, and prepares operators to act responsibly within defined safety limits, even when the training scope is strictly theoretical.

Click the Link: Criteria for Issuing Certificates in accordance with the Standards

Certificate of Completion

Boiler Operator Training English

BOILER OPERATOR TRAINING IN ENGLISH

Course Load: 16 Hours

Module 01 – Pressure Fundamentals (2 Hours)

Concept of pressure and its physical meaning

Atmospheric pressure and its influence on thermal systems

Gauge pressure and absolute pressure

Internal pressure, external pressure and vacuum

Pressure units and conversion between systems

Practical interpretation of pressure values in boiler operation

Module 02 – Heat and Temperature Fundamentals (3 Hours)

Definition of heat and temperature

Difference between heat and temperature

Modes of heat transfer: conduction, convection and radiation

Specific heat and sensible heat

Heat transfer at constant temperature

Thermal equilibrium and energy balance concepts

Module 03 – Thermodynamics Applied to Boilers (3 Hours)

Basic thermodynamic concepts

Thermodynamic systems and control volumes

State variables and properties

Saturated steam and superheated steam

Phase change and steam tables interpretation

Energy efficiency principles in steam generation

Module 04 – Fluid Mechanics Fundamentals (3 Hours)

Basic concepts of fluid mechanics

Pressure in fluid flow

Laminar flow and turbulent flow

Liquid flow mechanisms:

Flow by gravity

Flow by pressure difference

Siphon principle

Head loss concepts

Pipe roughness and flow disturbances

Fundamentals of fluid pumping

Module 05 – Applied Chemistry for Boiler Operation (3 Hours)

Basic concepts of applied chemistry

Density and its influence on fluid behavior

Solubility of substances in water

Diffusion of gases and vapors

Acids and bases characterization

pH definition and interpretation

Chemical balance in boiler systems

Module 06 – Corrosion Fundamentals in Boilers (2 Hours)

Basic concepts of corrosion

Electrochemical corrosion mechanisms

Factors influencing corrosion in boilers

Effects of corrosion on safety and efficiency

General prevention concepts and operational awareness

Completion and Certification:

Practical Exercises (when contracted);

Evidence Records;

Theoretical Evaluation;

Practical Evaluation (when contracted);

Certificate of Participation.

NOTE:

We emphasize that the General Normative Program Content of the Course or Training may be modified, updated, supplemented, or have items excluded as deemed necessary by our Multidisciplinary Team. Our Multidisciplinary Team is authorized to update, adapt, modify, and/or exclude items, as well as insert or remove Standards, Laws, Decrees, or technical parameters they consider applicable, whether related or not. The Contracting Party is responsible for ensuring compliance with the relevant legislation.

Boiler Operator Training English