Reference: 55594

NR33 Confined Spaces Training

The objective of the NR33 Confined Spaces Training is to provide workers with solid theoretical knowledge to safely perform activities in confined spaces, focusing on hazard recognition, risk assessment, and preventive control measures. Through a structured and technical approach, the training develops the ability to identify physical, chemical, biological, and ergonomic risks, while reinforcing the correct interpretation of safety procedures, permits, and protection systems applicable to confined environments. As a result, participants strengthen their situational awareness and decision making before, during, and after confined space activities.

Moreover, the course aims to ensure full compliance with NR 33, which is the principal regulatory standard governing these activities. By aligning legal requirements with practical understanding, the training promotes a proactive safety culture, reduces the likelihood of accidents such as asphyxiation and entrapment, and supports organizations in meeting their occupational health and safety obligations. Consequently, workers become more prepared to act responsibly, consistently, and in accordance with current regulatory standards.

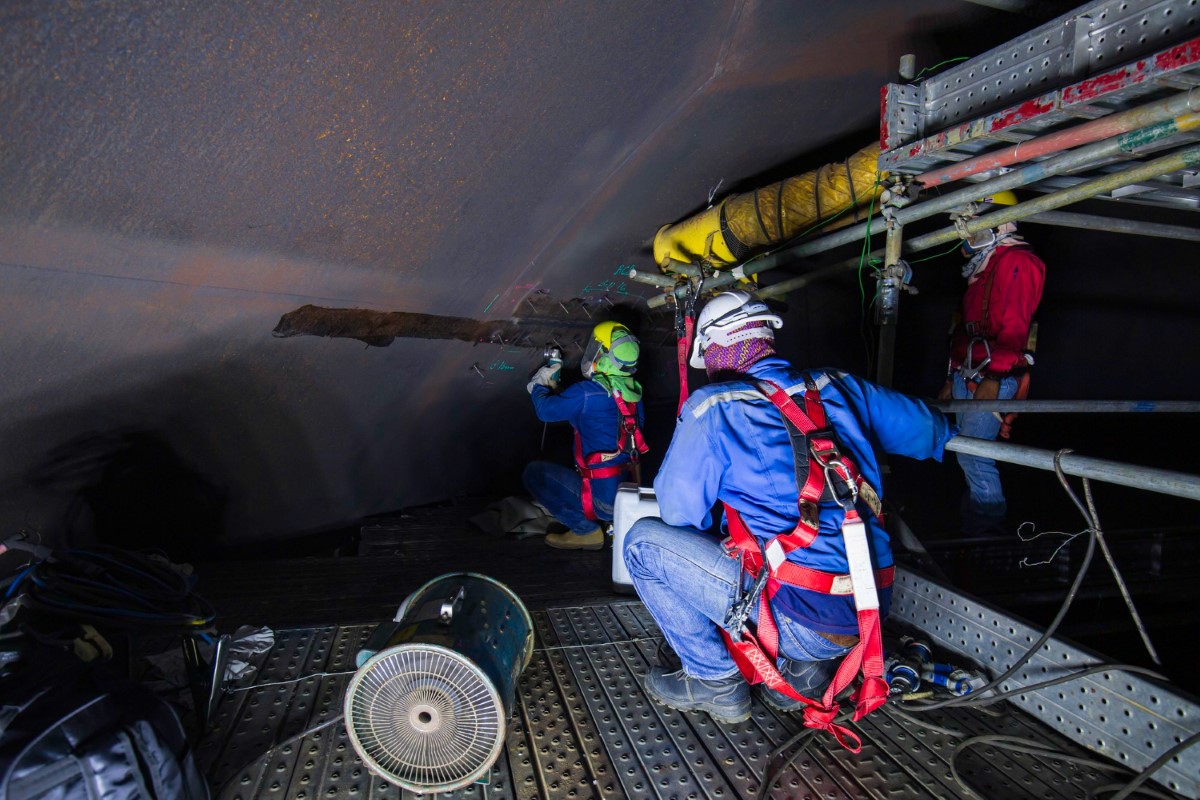

Safe work in confined spaces depends on coordinated teamwork, controlled access, and constant monitoring of environmental conditions to avoid asphyxiation and entrapment.

Who must attend confined space safety training?

Confined space safety training must be attended by all workers who perform activities in confined spaces, regardless of job title or duration of exposure. This includes authorized entrants, attendants, supervisors, and any personnel involved in planning or supporting confined space operations. By doing so, organizations ensure that every individual understands the hazards and responsibilities associated with these environments.

Moreover, the training reinforces legal compliance and risk awareness by aligning worker competence with the requirements of NR 33. Consequently, trained workers are better prepared to recognize unsafe conditions, follow established procedures, and prevent incidents before they escalate into serious accidents.

When is confined space training required?

Confined space training is required before a worker is authorized to enter or work in a confined space and whenever there are changes in procedures, hazards, or equipment. In addition, refresher training becomes necessary when incidents occur or when risk assessments identify new exposure scenarios.

Below is a summary of common situations that require training:

| Situation | Training Requirement |

|---|---|

| First assignment in confined space | Initial training before entry |

| Change in task or process | Updated training |

| Introduction of new hazards | Additional training |

| Incident or near miss | Retraining |

| Regulatory or procedural updates | Training review |

NR33 Confined Spaces Training: Confined spaces present immediate and severe risks

Confined spaces create high risk scenarios due to restricted access, limited ventilation, and rapidly changing atmospheric conditions. Therefore, understanding these risks is essential to prevent sudden and fatal incidents.

Main risk factors include

Limited oxygen availability

Accumulation of toxic or flammable substances

Restricted movement and difficult escape routes

Lack of natural ventilation

Delayed emergency response

Working inside confined environments demands effective ventilation, fall protection systems, and disciplined adherence to safety protocols to control multiple simultaneous risks.

Why is risk assessment essential before entering a confined space?

Risk assessment is essential because it allows hazards to be identified, evaluated, and controlled before exposure occurs. By systematically analyzing atmospheric conditions, physical constraints, and task-related risks, workers and supervisors can define effective control measures and prevent unpredictable scenarios.

Furthermore, risk assessment supports compliance with NR 33 by ensuring that entry permits, protective equipment, and emergency plans are based on real conditions rather than assumptions. As a result, organizations significantly reduce the probability of accidents and improve overall operational safety.

Where are confined spaces commonly found in the workplace?

Confined spaces are found in multiple industrial and construction environments, often in locations not immediately recognized as hazardous. Therefore, workers must be trained to identify them correctly.

Common examples include:

| Sector | Typical Confined Spaces |

|---|---|

| Construction | Shafts, pits, tanks |

| Industry | Silos, vessels, reactors |

| Utilities | Manholes, tunnels |

| Maintenance | Boilers, pipelines |

| Storage | Underground reservoirs |

NR33 Confined Spaces Training: Human factors directly influence confined space safety

Human behavior plays a decisive role in confined space safety, especially under pressure and unfamiliar conditions. Consequently, perception, emotion, and decision making can either prevent or trigger serious accidents.

Key human factors include

Fear and stress responses

Overconfidence due to routine exposure

Risk habituation over time

Fatigue and reduced attention

Improper interpretation of warning signs

What is the role of the Entry and Work Permit in confined space activities?

The Entry and Work Permit plays a critical role by formally authorizing access only after all hazards have been identified and controlled. It ensures that atmospheric testing, equipment inspection, communication, and emergency preparedness are verified before entry occurs.

Additionally, the permit functions as an active safety barrier rather than administrative paperwork. When correctly applied, it enforces discipline, accountability, and continuous monitoring, thereby supporting compliance with NR 33 and significantly reducing the risk of serious incidents.

Confined space entry requires continuous risk awareness, proper respiratory protection, and strict compliance with entry permit procedures to prevent sudden atmospheric hazards.

What is the important of the NR33 Confined Spaces Training?

The importance of the NR33 Confined Spaces Training lies in its role in preventing serious and fatal accidents in confined spaces by ensuring that workers understand the hazards before exposure occurs. Through structured theoretical training, participants develop the ability to recognize atmospheric, physical, chemical, biological, and ergonomic risks, while applying appropriate control measures and safe work procedures. As a result, the course strengthens risk perception, improves decision making, and reduces unsafe behaviors that commonly lead to incidents such as asphyxiation, entrapment, and emergency response failures.

Furthermore, the course is essential for legal and regulatory compliance, as it is directly aligned with NR 33, the principal standard governing these activities. By meeting NR 33 requirements, organizations demonstrate due diligence, reinforce a proactive safety culture, and protect both workers and employers from operational, legal, and reputational consequences. Consequently, the training becomes a critical barrier for accident prevention and a fundamental element of occupational health and safety management systems.

Click the Link: Criteria for Issuing Certificates in accordance with the Standards

Certificate of Completion

NR33 Confined Spaces Training

TRAINING FOR WORKERS WHO PERFORM ACTIVITIES IN CONFINED SPACES IN ENGLISH

Course Load: 16 Hours

MODULE 1 – Fundamentals of Confined Space Safety (2 Hours)

Concept and definition of confined spaces

Characteristics and classification of confined spaces

Confined spaces in the construction industry

Legal responsibilities of workers and employers

Overview of occupational health and safety principles

Introduction to accident prevention culture

MODULE 2 – Applicable Legislation and Standards (2 Hours)

Regulatory Standard NR 33 – Safety and Health in Confined Spaces

Interpretation of legal and normative requirements

Employer and worker duties under Brazilian labor legislation

Civil, administrative, and criminal liabilities

MODULE 3 – Hazard Identification and Risk Recognition (2 Hours)

Imminent hazards in confined space activities

Physical risks

Chemical risks

Biological risks

Ergonomic risks

Atmospheric hazards

Oxygen-deficient and oxygen-enriched environments

Recognition of potential accident scenarios

MODULE 4 – Risk Assessment and Control Measures (2 Hours)

Risk assessment concepts and methodology

Evaluation and control of confined space risks

Hierarchy of control measures

Engineering controls

Administrative controls

Operational procedures

Collective Protection Equipment (EPCs)

Criteria for selection and use of safety equipment

MODULE 5 – Safety Equipment and Protection Systems (2 Hours)

Personal Protective Equipment (PPE)

Fall protection systems

Respiratory protection

Respiratory Protection Program

Protection against confinement and engulfment

Operation principles of safety equipment

Functionality and limitations of protection systems

Daily inspection requirements for safety equipment

MODULE 6 – Work Authorization and Operational Procedures (2 Hours)

Entry Permit and Work Permit systems

Permit to Enter and Work (PET)

Safe work procedures in confined spaces

Monitoring and supervision requirements

Area classification concepts

Communication and signaling procedures

Operational discipline and compliance

MODULE 7 – Emergency Response and Accident Analysis (2 Hours)

Emergency response procedures

Accidents involving asphyxiation

Initial response to confined space incidents

Basic notions of rescue in confined spaces

Emergency communication protocols

Principles of first aid in confined space scenarios

Accident investigation and lessons learned

MODULE 8 – Human Factors, Ergonomics, and Risk Perception (2 Hours)

Risk perception and influencing factors

Behavioral factors impacting safety

The fear factor and decision-making under stress

Consequences of risk habituation

Importance of task knowledge and situational awareness

Basic ergonomics concepts

Workstation analysis

Manual handling of loads and posture

Ergonomic risk Prevention

Completion and Certification:

Practical Exercises (when contracted);

Evidence Records;

Theoretical Evaluation;

Practical Evaluation (when contracted);

Certificate of Participation.

NOTE:

We emphasize that the General Normative Program Content of the Course or Training may be modified, updated, supplemented, or have items excluded as deemed necessary by our Multidisciplinary Team. Our Multidisciplinary Team is authorized to update, adapt, modify, and/or exclude items, as well as insert or remove Standards, Laws, Decrees, or technical parameters they consider applicable, whether related or not. The Contracting Party is responsible for ensuring compliance with the relevant legislation.

NR33 Confined Spaces Training