Technical Name: SAFETY TRAINING FOR WORKERS WHO INTERVENE IN ENERGIZED HIGH-VOLTAGE ELECTRICAL INSTALLATIONS IN THE ELECTRIC POWER SYSTEM IN ENGLISH

Referência: 55731

NR10 SEP Training English

The objective of this course is to develop solid technical awareness for professionals who intervene in energized high-voltage electrical installations within the Electric Power System. Therefore, the training focuses on understanding risks, recognizing limiting conditions, and applying structured methods for planning, communication, and decision-making. By doing so, participants strengthen their ability to interpret operational scenarios, anticipate hazards, and act with technical consistency in complex and high-risk environments.

Furthermore, the course aims to align professional conduct with the principles, requirements, and safety logic established by NR 10, which serves as the main regulatory reference. As a result, workers consolidate theoretical competence to operate responsibly, reduce exposure to critical risks, and support safe, organized, and traceable electrical activities, even under demanding operational conditions involving energized high-voltage systems.

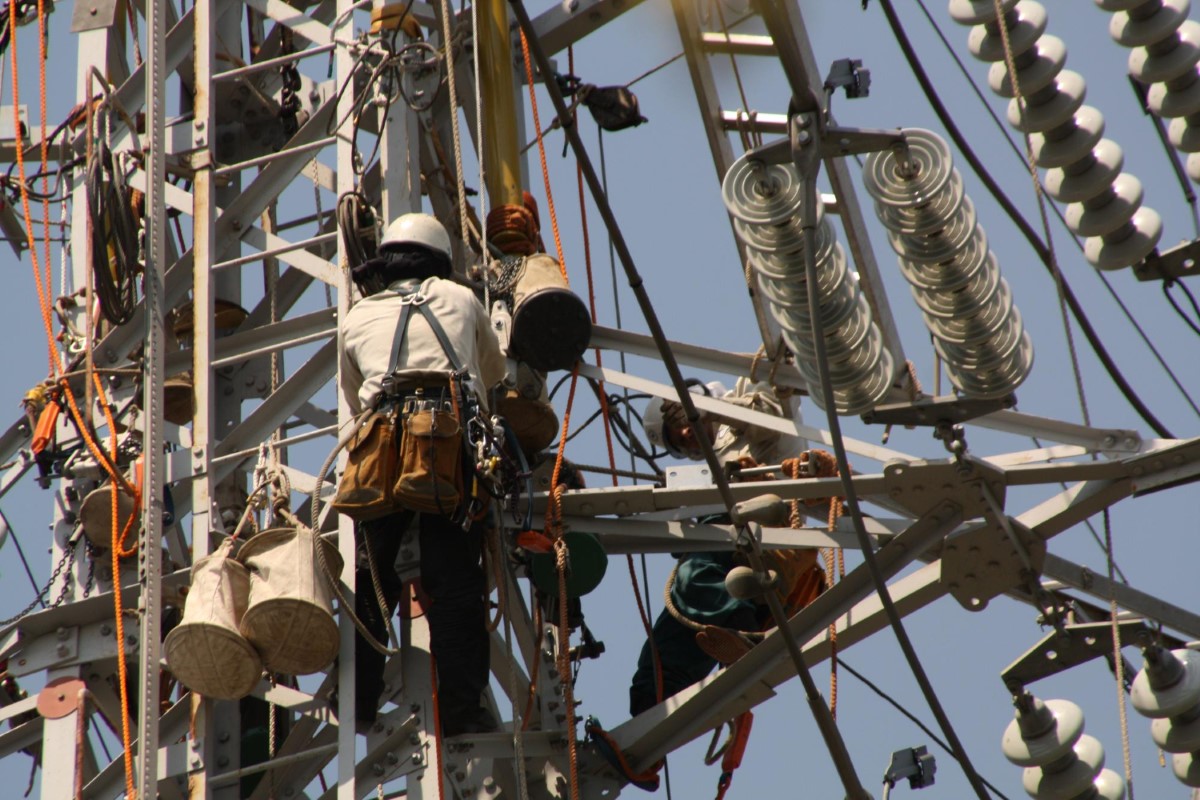

Working on transmission structures highlights the complexity of energized environments, where induction, electric fields, and human behavior converge as critical risk factors.

Who is qualified to intervene in energized high-voltage electrical installations?

Professionals who intervene in energized high-voltage installations must demonstrate technical competence, situational awareness, and the ability to understand complex electrical environments. Therefore, qualification goes beyond formal training and depends on the capacity to interpret risks, follow structured procedures, and act responsibly under critical conditions.

Moreover, these workers must understand the Electric Power System as an integrated structure. As a result, they can anticipate hazards, respect operational limits, and contribute to collective safety, even when performing tasks in high-risk and time-sensitive scenarios.

When should energized work be planned and authorized?

Before any intervention, planning becomes the decisive factor for safety. Consequently, energized work must only occur after careful evaluation of conditions, risks, and operational feasibility.

The table below summarizes the key moments that require planning and authorization.

| Planning Stage | Purpose | Safety Impact |

|---|---|---|

| Service scheduling | Define timing and sequence | Prevents rushed decisions |

| Risk evaluation | Identify hazards | Reduces unexpected exposure |

| Authorization review | Confirm readiness | Ensures controlled execution |

| Final verification | Validate conditions | Prevents unsafe start |

NR10 SEP Training English: Technical competence defines safe intervention

This statement reinforces that safety in energized high-voltage systems depends directly on knowledge, discipline, and technical judgment. Without these elements, even well-designed systems become vulnerable.

Key aspects involved

Understanding system behavior

Recognizing limiting conditions

Applying standardized methods

Maintaining operational discipline

High-voltage energized work requires absolute control of distance, communication, and positioning, since proximity alone can trigger electrical arcs even without direct contact.

Why is communication critical in high-voltage energized operations?

Because energized environments allow little margin for error, communication becomes a primary safety barrier. Therefore, clear, direct, and standardized communication prevents misunderstandings that could escalate into severe incidents.

In addition, effective communication aligns teams, synchronizes actions, and reinforces situational awareness. As a consequence, it supports coordinated decision-making and reduces the likelihood of unsafe assumptions during complex operations.

Where do the most critical risks occur within the Electric Power System?

Critical risks concentrate in areas where energy remains present, even when systems appear controlled. Thus, recognizing these zones is essential for safe intervention.

The table below highlights typical high-risk locations.

| Location | Main Risk | Reason |

|---|---|---|

| Near energized conductors | Electrical arc | Reduced air insulation |

| Grounding areas | Step and touch voltage | Potential differences |

| Adjacent live lines | Induction | Unintended energization |

| Substations | Combined hazards | High energy density |

NR10 SEP Training English: Proximity control prevents most serious accidents

This affirmation emphasizes that controlling distance from energized parts is one of the most effective safety measures. When professionals respect approach limits, they significantly reduce the likelihood of arcs and unintended contact.

Key elements of proximity control

Defined safe distances

Visual identification of energized zones

Continuous situational awareness

Strict adherence to operational limits

How does risk analysis support decision-making in energized work?

Risk analysis transforms uncertainty into structured understanding. Therefore, it allows professionals to identify hazards, evaluate exposure, and define control measures before execution.

Furthermore, when applied consistently, risk analysis supports informed decisions, strengthens operational discipline, and reinforces a safety-focused mindset. As a result, it becomes a decisive tool for reducing incidents in energized high-voltage environments.

Interventions in the Electric Power System demand precise coordination and situational awareness, ensuring that every movement respects the limits imposed by energized conductors.

What is the important of the NR10 SEP Training English?

The importance of this course lies in preparing professionals to understand and manage the complex risks involved in interventions on energized high-voltage electrical installations within the Electric Power System. Therefore, the training strengthens technical awareness, improves risk perception, and promotes disciplined decision-making. By mastering these elements, workers reduce exposure to critical hazards, avoid unsafe assumptions, and contribute to safer and more reliable electrical operations.

Furthermore, this course aligns professional conduct with the principles and requirements established by NR 10, which is the main regulatory reference for electrical safety. As a result, participants consolidate theoretical competence, reinforce responsibility, and support compliance, operational continuity, and accident prevention in environments where errors have severe and often irreversible consequences.

Click the Link: Criteria for Issuing Certificates in accordance with the Standards

Certificate of Completion

NR10 SEP Training English

SAFETY TRAINING FOR WORKERS WHO INTERVENE IN ENERGIZED HIGH-VOLTAGE ELECTRICAL INSTALLATIONS IN THE ELECTRIC POWER SYSTEM IN ENGLISH

Workload: 40 Hours

MODULE 1 – Fundamentals of the Electric Power System and High-Voltage Context (5 Hours)

Concepts and structure of the Electric Power System

Characteristics of energized high-voltage installations

Operational logic of generation, transmission and distribution

Roles and responsibilities of workers involved in energized systems

General principles of electrical safety in high-voltage environments

MODULE 2 – Organization, Planning and Service Programming (5 Hours)

Organization of electrical installations

Service programming and activity sequencing

Technical and operational planning

Documentation management and technical records

Installation registry and information traceability

Importance of accurate and updated technical data

MODULE 3 – Work Methods, Communication and Behavioral Influence (5 Hours)

Work methods applied to energized electrical systems

Operational communication processes

Identification and standardization of information

Influence of human behavior on safety performance

Risk perception and decision-making

Conditions that prevent or interrupt services

MODULE 4 – Typical Risks in the Electric Power System (5 Hours)

Risks associated with energized installations

Proximity risks and unsafe approach distances

Contact with energized parts

Electrical induction effects

Atmospheric discharge exposure

Static electricity phenomena

Electric and magnetic field exposure

MODULE 5 – Risk Prevention and Safety Methods in Operations (5 Hours)

Preventive measures for electrical risks

Safety methods in energized operations

Control of exposure and proximity

Management of additional and combined risks

Application of risk control strategies

Integration of preventive actions into daily operations

MODULE 6 – Risk Analysis and Occupational Procedures (5 Hours)

Principles of risk analysis

Hazard identification and risk evaluation

Development and application of occupational procedures

Critical review and discussion of procedures

Decision criteria for safe work execution

Documentation of risk management actions

MODULE 7 – Equipment, Tools and Protection Systems (5 Hours)

Work equipment and operational tools

Criteria for selecting appropriate equipment

Correct use of tools and instruments

Conservation and functional verification

Collective protection systems

Personal protection equipment

Work postures, clothing and operational discipline

MODULE 8 – Operational Safety, Accidents and Responsibilities (5 Hours)

Safety in vehicle use and transportation of people, materials and equipment

Signaling and isolation of work areas

Release of installations for service, operation and use

Typical accidents in high-voltage environments

Accident analysis and critical discussion

Preventive measures against accidents

Emergency response concepts and victim handling fundamentals

Individual and organizational responsibilities

Completion and Certification:

Practical Exercises (when contracted);

Evidence Records;

Theoretical Evaluation;

Practical Evaluation (when contracted);

Certificate of Participation.

NOTE:

We emphasize that the General Normative Program Content of the Course or Training may be modified, updated, supplemented, or have items excluded as deemed necessary by our Multidisciplinary Team. Our Multidisciplinary Team is authorized to update, adapt, modify, and/or exclude items, as well as insert or remove Standards, Laws, Decrees, or technical parameters they consider applicable, whether related or not. The Contracting Party is responsible for ensuring compliance with the relevant legislation.

NR10 SEP Training English