Technical Name: CRANE EQUIPMENT OPERATOR TRAINING COURSE NR 18 – SAFETY AND HEALTH CONDITIONS AT WORK IN THE CONSTRUCTION INDUSTRY

Reference: 170989

We provide courses and training; We perform Translations and Versions in Technical Language: Portuguese, English, Spanish, French, Italian, Mandarin, German, Russian, Swedish, Dutch, Hindi, Japanese and others consult.

Crane Equipment Course NR18

The objective of the Crane Equipment Course NR18 is to provide participants with a solid theoretical foundation to recognize hazards, understand risk scenarios and apply safety principles related to crane operations in the construction environment. Through structured technical content, the course develops risk perception, critical thinking and decision-making skills, enabling professionals to identify unsafe conditions, analyze protection systems and understand the consequences of improper operation before accidents occur.

Furthermore, the course aligns its content with the requirements established by NR 18, which serves as the main regulatory reference for crane-related activities in construction. By doing so, it ensures that participants understand their responsibilities, the limits of safe operation and the importance of planning, communication and preventive measures, reinforcing a safety-oriented mindset essential for reducing incidents and preserving lives.

Proper load handling and rigging control during cable coil lifting, emphasizing risk awareness, communication and safe positioning during crane operations.

Who should attend the Crane Equipment Operator Training Course?

In construction environments, crane operations involve multiple roles that influence safety outcomes, not only the individual at the controls. Therefore, this course is structured for professionals who participate in planning, supervision and decision-making related to lifting activities, requiring a solid theoretical understanding of risks and safety principles.

Additionally, the course supports those who must evaluate conditions, authorize operations and intervene when unsafe situations arise. By reinforcing technical judgment and risk awareness, it helps ensure that responsibilities are exercised with consistency and safety focus.

When should theoretical crane operator training be conducted?

The effectiveness of crane safety training depends strongly on timing. When theoretical knowledge is delivered at the right moment, it prevents exposure to unmanaged risks and strengthens safe behavior before incidents can occur.

| Situation | Recommended Timing |

|---|---|

| New professionals entering crane-related activities | Before any operational involvement |

| Change of equipment or work conditions | Prior to the new activity |

| After incidents or near misses | Immediately, as corrective reinforcement |

| Periodic safety reviews | At defined intervals |

Crane Equipment Course NR18: Risk awareness is built before the crane starts moving

Safe lifting operations begin long before any mechanical movement takes place. Early risk awareness allows hazards to be identified, evaluated and controlled while decisions can still be adjusted.

Identification of hazards before lifting

Analysis of load characteristics and environment

Evaluation of protections and limitations

Definition of safe operational boundaries

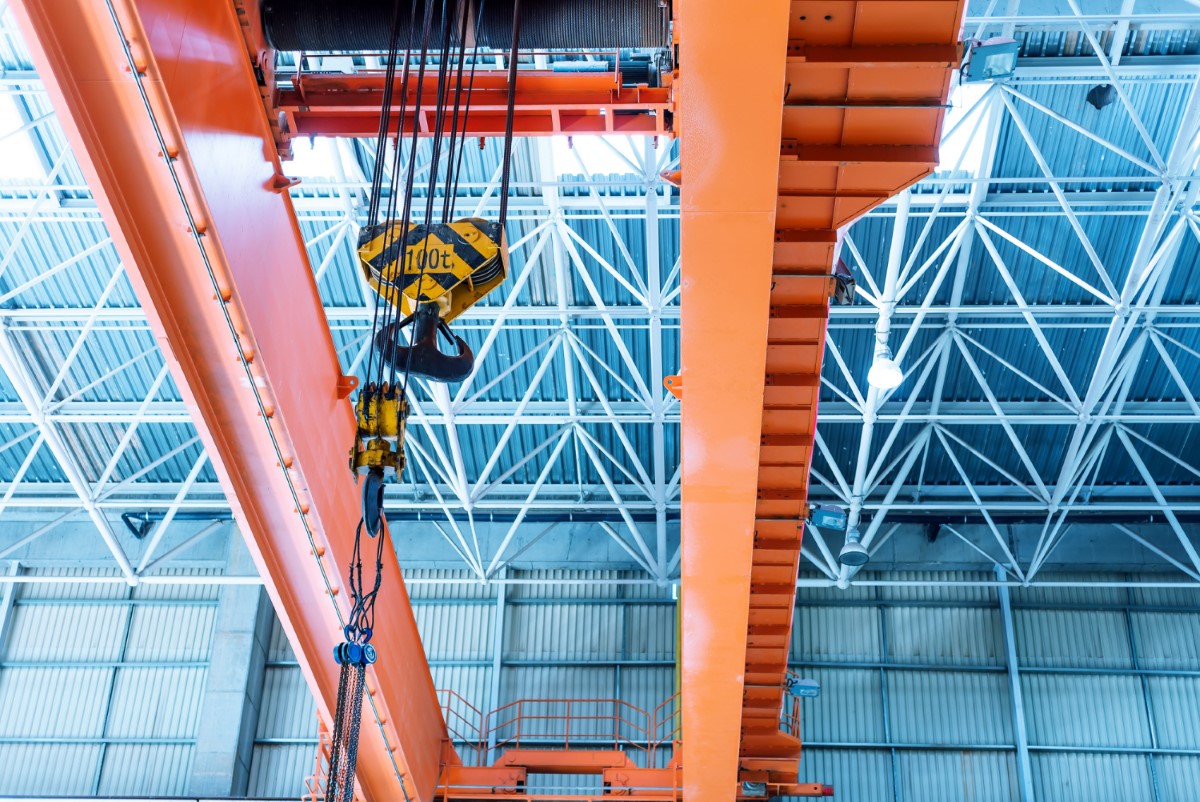

Overhead crane system highlighting structural components, lifting mechanism and the importance of understanding load limits and suspended load risks in construction environments.

Why is theoretical knowledge essential even for experienced operators?

Although experience improves intuition, it does not replace technical understanding. Theory provides the structure needed to interpret complex scenarios, recognize hidden hazards and understand how failures develop under specific conditions.

Furthermore, theoretical knowledge supports consistent decision-making during unexpected events. Instead of relying solely on habit, experienced professionals can apply proven safety principles, reducing uncertainty and preventing critical errors.

Where do most crane-related risks originate?

Crane-related risks rarely arise from a single isolated factor. In most cases, they result from the interaction between equipment condition, environmental factors and human behavior.

| Risk Source | Typical Examples |

|---|---|

| Equipment | Mechanical failure, worn components |

| Environment | Poor ground conditions, wind |

| Organization | Lack of planning, unclear communication |

| Human factors | Misjudgment, overconfidence |

Crane Equipment Course NR18: Safe operations depend on planning, communication and control

Consistent safety in crane operations is achieved through coordinated actions rather than individual effort. Clear planning, effective communication and active control form the foundation of safe lifting activities.

Structured operational planning

Clear communication between team members

Control of access and exclusion zones

Continuous monitoring of conditions

How does the course contribute to accident prevention in construction sites?

The course contributes by shifting the focus from reactive responses to proactive risk management. Participants learn to recognize unsafe conditions early, understand the role and limits of protections and evaluate operational decisions before execution.

As a result, this structured approach reduces incident probability, improves operational discipline and reinforces a preventive mindset aligned with NR 18, supporting safer and more controlled construction environments.

Bridge crane operating inside an industrial facility, illustrating critical safety concepts related to overhead movement, exclusion zones and suspended load control.

What is the important of the Crane Equipment Course NR18?

The importance of the Crane Equipment Course NR18 lies in its role in building a solid theoretical foundation for safe decision-making in lifting operations within construction environments. By addressing risk recognition, protection systems and safe working principles, the course enables professionals to anticipate hazardous situations, understand operational limits and reduce the likelihood of accidents caused by misjudgment, poor planning or overconfidence.

In addition, the course is essential for aligning professional practice with the requirements established by NR 18, which governs crane and lifting activities in construction sites. Through this alignment, participants strengthen their safety culture, improve operational discipline and contribute directly to safer worksites, protecting both people and assets.

Click the Link: Criteria for Issuing Certificates in accordance with the Standards

Certificate of Completion

Crane Equipment Operator Course

CRANE EQUIPMENT OPERATOR TRAINING COURSE NR 18 – SAFETY AND HEALTH CONDITIONS AT WORK IN THE CONSTRUCTION INDUSTRY

Course Load: 80 Hours

Module 1 – Fundamentals of Safety and Responsibility (6 Hours)

General principles of occupational safety applied to crane operations

Roles and responsibilities of operators, supervisors and organizations

Concepts of safe work and risk perception

Consequences of unsafe acts and unsafe conditions

Professional conduct and decision-making in critical situations

Module 2 – Crane Equipment Classification and Characteristics (6 Hours)

Types of crane equipment used in construction activities

General description of structural components

Theoretical principles of crane operation

Rated capacity, load charts and operational limits

Common construction scenarios involving crane equipment

Module 3 – Risk Identification and Hazard Recognition (8 Hours)

Description and identification of risks associated with crane equipment

Mechanical hazards

Electrical hazards

Structural instability and overturning risks

Load handling and suspended load hazards

Environmental and surrounding area risks

Human factors and organizational risks

Module 4 – Safety Protections and Safety Devices (6 Hours)

Types of safety protections applied to crane equipment

Collective protection systems

Warning, alarm and signaling devices

Blocking and interlocking systems

Limiters and control mechanisms

Theoretical evaluation of protection effectiveness

Module 5 – Operation and Proper Use of Protections (6 Hours)

Principles for correct use of safety protections

Functioning logic of protection systems

Limitations and operational boundaries of protections

Risks arising from improper use or neglect

Behavioral factors influencing protection effectiveness

Module 6 – Removal, Damage and Failure of Protections (6 Hours)

Risks associated with removal of safety protections

Analysis of damaged or compromised protections

Failure modes of safety devices

Operational consequences of working without protections

Reporting and communication of unsafe conditions

Module 7 – Mechanical, Electrical and Associated Risks (6 Hours)

Mechanical risk scenarios in crane operations

Electrical hazard situations

Interaction between crane equipment and external energy sources

Environmental influences on risk exposure

Preventive concepts for risk reduction

Module 8 – Safe Working Methods and Operational Planning (6 Hours)

Concept of safe working methods

Task planning and sequencing

Work authorization concepts

Communication and coordination during operations

Control of access and isolation of work areas

Module 9 – Blocking, Inspection and Maintenance Concepts (6 Hours)

Concept of operational blocking systems

Importance of isolation before inspection and maintenance

Inspection principles and visual checks

Cleaning and lubrication concepts

Maintenance awareness and risk prevention

Module 10 – Traffic, Signage and Workplace Circulation (6 Hours)

Notions of traffic rules applicable to construction environments

Internal circulation and vehicle interaction

Safety signage principles

Visual communication and standard signals

Prevention of collision and run-over risks

Module 11 – Accidents, Occupational Diseases and Risk Control Measures (6 Hours)

Basic concepts of work-related accidents

Typical accidents involving crane equipment

Health effects of exposure to mechanical and physical risks

Risk control strategies

Collective protection measures

Personal protection measures

Module 12 – Emergency Procedures and First Aid Awareness (6 Hours)

Emergency situations involving crane operations

Immediate response principles

Evacuation and isolation concepts

Notions of first aid

Importance of preparedness and calm response

Module 13 – Means of Access to Machinery and Equipment (4 Hours)

Safe access concepts for machinery and equipment

Ladders, platforms and walkways

Fall prevention principles

Risk awareness during access and movement

Completion and Certification:

Practical Exercises (when contracted);

Evidence Records;

Theoretical Evaluation;

Practical Evaluation (when contracted);

Certificate of Participation.

NOTE:

We emphasize that the General Normative Program Content of the Course or Training may be modified, updated, supplemented, or have items excluded as deemed necessary by our Multidisciplinary Team. Our Multidisciplinary Team is authorized to update, adapt, modify, and/or exclude items, as well as insert or remove Standards, Laws, Decrees, or technical parameters they consider applicable, whether related or not. The Contracting Party is responsible for ensuring compliance with the relevant legislation.

Crane Equipment Operator Course