Technical Name: RESCUE AND REMOVAL IN ACTIVITIES IN DEEP FOUNDATION COURSE NR 18 – SAFETY AND HEALTH CONDITIONS AT WORK IN THE CONSTRUCTION INDUSTRY

Reference: 171038

We provide courses and training; We perform Translations and Versions in Technical Language: Portuguese, English, Spanish, French, Italian, Mandarin, German, Russian, Swedish, Dutch, Hindi, Japanese and others consult.

Caisson Rescue Course English

The Caisson Rescue Course English aims to train the professional to identify, assess, and control the risks present in deep foundation activities, especially those that constitute confined spaces. By understanding how hazardous atmospheres form, how access must be controlled, and how ventilation must be evaluated, the participant develops technical autonomy to recognize unsafe conditions and act preventively.

The training also seeks to strengthen the worker’s response capacity in emergency scenarios. Through the study of removal procedures, atmospheric monitoring, energy isolation, and the organization of the rescue plan, the participant begins to understand how to make rapid and well-founded decisions. Thus, the course aligns regulatory theory, risk perception, and rescue strategies, ensuring safer interventions and performance compatible with the legal and operational demands of the construction sector.

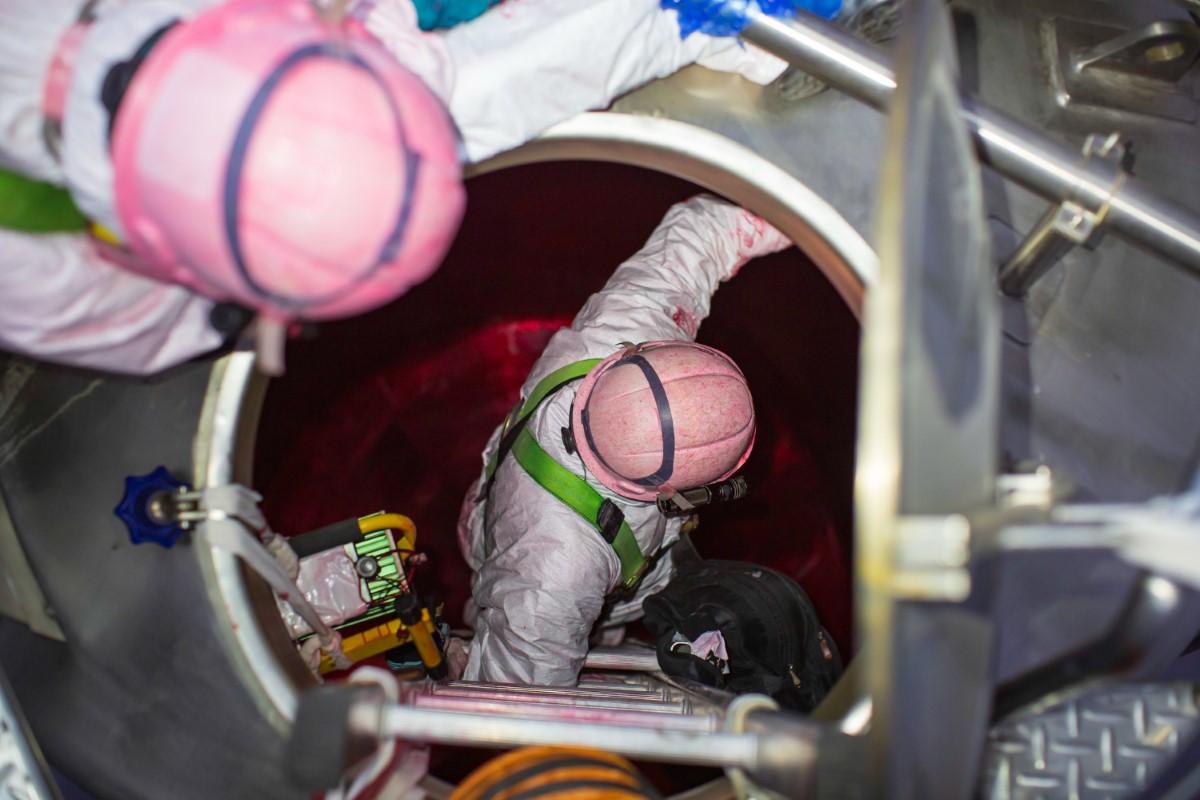

Rescue team entering a confined vessel with full PPE, direct-reading instruments and controlled descent for emergency operations.

Who is responsible for ensuring safe entry into deep foundation confined spaces?

Safe entry into deep foundation confined spaces depends on trained professionals who understand atmospheric monitoring and the access control. These workers must anticipate structural and atmospheric hazards, interpret risk indicators and apply preventive actions before any descent into a confined vertical environment.

The employer must also guarantee that authorization procedures, continuous atmosphere monitoring and the rescue plan are implemented and functioning as a unified system. When responsibilities are clearly defined and safety layers are synchronized, entries occur under real safety margins, significantly reducing the potential for collapse, toxic exposure or entrapment.

When must atmosphere testing be conducted during deep foundation work?

Atmospheric testing must be performed at strategic phases of deep foundation confined space operations because internal air conditions can shift rapidly due to limited ventilation, soil emissions, tool operation or human respiration, making continuous verification essential to prevent oxygen deficiency, toxic buildup or flammable environments.

Mandatory Moments for Atmospheric Testing

| Stage of Activity | Required Atmospheric Testing |

|---|---|

| Before entry | Full initial evaluation |

| During work | Continuous or periodic monitoring according to risk level |

| After interruptions | New testing before re-entry |

| During victim removal | Immediate verification before rescue begins |

Caisson Rescue Course English: Where atmospheric hazards develop quickly

Deep foundation confined spaces experience rapid atmospheric deterioration because of restricted air movement, vertical geometry and natural gas emissions from the soil, which together create an environment where unsafe conditions can form unexpectedly.

Accumulation of carbon dioxide from human respiration

Natural toxic gases migrating from subsurface layers

Oxygen displacement due to poor circulation

Flammability risk from trapped vapors

Confined space inspection inside a deep corrugated shaft with controlled access, atmospheric monitoring and lifeline protection.

Why does the rescue plan need to be fully defined before entry?

The rescue plan must be fully defined before entry because emergencies unfold at high speed in deep vertical confined spaces, where limited mobility, reduced visibility and difficult access eliminate the possibility of improvisation. When the team relies on predetermined procedures, roles and communication channels, they avoid delays that could compromise the survival of the worker inside the shaft.

Furthermore, anticipating critical scenarios enables the team to reduce response time and maintain operational control under pressure. A structured rescue plan ensures that both the victim and the rescuers remain protected, aligning the activity with the preventive requirements of NR 18 and NR 33 and eliminating unnecessary exposure to high-risk conditions.

What elements must be evaluated before permitting manual shaft entry?

Before workers are allowed to enter a manually excavated shaft, a comprehensive evaluation must confirm that structural stability, air quality, access conditions and communication systems meet the minimum safety standards required for deep confined space entry.

Elements That Must Be Evaluated

| Element | Required Verification |

|---|---|

| Structural stability | Condition of lining and absence of collapse indicators |

| Internal atmosphere | Oxygen level, toxic gases and flammability |

| Vertical access | Integrity of ladders, ropes and anchorage points |

| Ventilation | Effectiveness of forced or natural air renewal |

| Communication | Functional surface-to-bottom communication system |

Caisson Rescue Course English: Who conducts the immediate abandonment of the site

Immediate abandonment must occur the moment a severe and imminent risk is detected, requiring quick recognition, coordinated withdrawal and immediate operational shutdown to prevent escalation.

Trained worker identifies the condition

Team halts activities instantly

Supervisor confirms task suspension

Area remains isolated until reassessed

Where does risk escalation occur most often in deep foundation rescue operations?

Risk escalation occurs most frequently in areas with severely restricted ventilation and limited movement . These zones require heightened situational awareness and strict adherence to preventive measures.

A second critical point arises during victim extraction, when space constraints limit maneuverability and the team must maintain full control of lifting systems, load distribution and shaft stability. This combination of vertical confinement, operational complexity and real-time hazard interaction increases the likelihood of escalation, reinforcing the need for advanced preparation and disciplined execution.

Worker performing safe vertical entry using a secured ladder, following confined space entry procedures and continuous monitoring.

What is the important of Caisson Rescue Course English?

The importance of the Caisson Rescue Course English lies in developing the worker’s ability to analyze, anticipate and control the unique hazards present in deep foundation environments, which often function as confined spaces with rapid atmospheric changes and heightened structural risks. By understanding how to evaluate oxygen levels, toxic gases, ventilation conditions and access limitations, participants build the technical competence required to prevent severe incidents, reinforcing a proactive safety culture aligned with NR 18, the principal regulation governing safety and health in the construction industry.

The course also strengthens the worker’s capacity to respond effectively to emergencies, especially in rescue and removal scenarios where vertical confinement, limited visibility and restricted mobility demand precise and informed actions. Through exposure to procedural logic, regulatory frameworks and rescue planning strategies, participants gain a clear understanding of how to perform interventions without compromising their own safety or that of their teammates. This integration of technical knowledge and regulatory compliance ensures safer operations and compliance with national requirements for deep foundation activities.

Click the Link: Criteria for Issuing Certificates in accordance with the Standards

Certificate of Completion

Rescue in Activities in Deep Foundation Course

RESCUE AND REMOVAL IN ACTIVITIES IN DEEP FOUNDATION COURSE NR 18 – SAFETY AND HEALTH CONDITIONS AT WORK IN THE CONSTRUCTION INDUSTRY

Course Load: 08 Hours

Module 1 – Safety and Health Management in Deep Foundation and Confined Spaces (1 Hour)

Identification of confined spaces and deep foundation areas according to NR 18 and NR 33

Isolation, lockout, blocking, sealing and signaling to prevent unauthorized access

Risk anticipation, recognition and evaluation of physical, chemical, biological, ergonomic and mechanical hazards

Implementation of preventive and protective measures according to NR 01

Module 2 – Technical Preventive Measures and Atmospheric Hazard Control (1 Hour)

Atmospheric hazard elimination or controlled reduction in confined spaces

Assessment of confined space atmosphere before and during entry

Acceptable atmospheric conditions for entry and continuous work

Continuous atmosphere monitoring using intrinsically safe equipment

Calibration, verification and electromagnetic protection of direct-reading meters

Module 3 – Access, Stay Conditions and Safety Requirements in Confined Spaces (1 Hour)

Secure access and stay conditions according to regulatory criteria

Ventilation analysis including oxygen concentration requirements

Testing of measuring equipment before each use

Entry authorization requirements and documentation

Module 4 – Deep Foundation Risks and Pile Driver Safety (1 Hour)

Identification of serious and imminent risk conditions near pile drivers

Understanding of pestle operational risk factors

Procedures for immediate site abandonment in hazardous scenarios

Communication of risks in activity development areas

Module 5 – Manual Excavation Requirements for Shafts and Deep Foundations (1 Hour)

Normative requirements for manually excavated shafts

Hooding requirements for all manually excavated shafts

Mandatory geotechnical study for excavations deeper than 3 meters

Minimum diameter specification of 0.9 m

Requirements for excavation above or below water level

Module 6 – Administrative and Organizational Safety Measures (1 Hour)

Planning, organization and execution of activities in deep foundations

Administrative measures for risk prevention

Personal measures linked to training, authorization and worker competency

Application of Entry and Work Permit (PET) according to NR 33

Module 7 – Emergency, Rescue and Removal Management (1 Hour)

Rescue and removal plan for deep foundation and confined space environments

Emergency procedures aligned with NR 18 and NR 33 principles

Integration of technical, administrative, personal and emergency measures

Criteria for ensuring secure environments throughout all work phases

Module 8 – PPE, Collective Protection and Construction Site Requirements (1 Hour)

Correct use of personal protective equipment

Collective protective equipment required at construction sites

Interaction with the Construction Site PGR (Risk Management Program)

Ensuring permanent maintenance of adequate working conditions

Completion and Certification:

Practical Exercises (when contracted);

Evidence Records;

Theoretical Evaluation;

Practical Evaluation (when contracted);

Certificate of Participation.

NOTE:

We emphasize that the General Normative Program Content of the Course or Training may be modified, updated, supplemented, or have items excluded as deemed necessary by our Multidisciplinary Team. Our Multidisciplinary Team is authorized to update, adapt, modify, and/or exclude items, as well as insert or remove Standards, Laws, Decrees, or technical parameters they consider applicable, whether related or not. The Contracting Party is responsible for ensuring compliance with the relevant legislation.

Rescue in Activities in Deep Foundation Course